Description

Waterjet 90k Intensifier

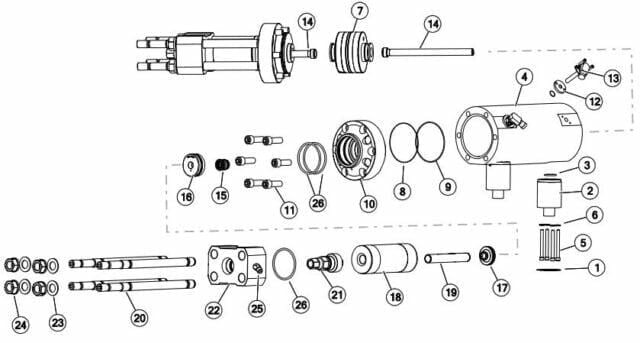

Waterjet 90k Intensifier Assembly 72170165

| Item | Part Number | Description | Quantity | Item | Part Number | Description | Quantity |

| 1 | 05146592 | Gasket, Topworks Support | 2 | 14 | 72162253 | Plunger | 2 |

| 2 | 20476377 | Apoyo, Topworks | 2 | 15 | 05130091 | Hydraulic Seal Cartridge | 2 |

| 3 | 10118206 | O-Ring, 1.31×1.56× .13 | 2 | 16 | 72175989 | Bushing Retainer Flange | 2 |

| 4 | 05144514 | Hydraulic Cylinder | 1 | 17 | 72158494 | UHP Seal Assembly | 2 |

| 5 | 05098991 | Socket Head Screw, 3/8-16×3-3/4 | 8 | 18 | 72166738 | UHP Cylinder | 2 |

| 6 | 95688743 | Lock Washer, .38 | 8 | 19 | 72163802 | Liner | 2 |

| 7 | 72101190 | Piston Assembly | 1 | 20 | 20474325 | Stud, 1-1/8-12×18.31 | 8 |

| 8 | 10074771 | O-Ring, 5.25×5.50× .13 | 2 | 21 | 72170157 | Sealing Head Assembly | 2 |

| 9 | 05120092 | Backup Ring, 5.25×5.50× .13 | 2 | 22 | 72178493 | Flange Assembly | 2 |

| 10 | 72175997 | Hydraulic Cylinder Head | 2 | 23 | 20464590 | Flat Washer, 1.13 | 8 |

| 11 | 05097886 | Socket Head Screw, 3/4-16×2-1/4 | 12 | 24 | 20461761 | Hex Nut, 1-1/8-12 | 8 |

| 12 | 05144183 | Spacer Assembly, Proximity Switch | 2 | 25 | 20489339 | Adapter, JIC/Pipe, 50× .38 | 1 |

| 05144191 | O-Ring, .69× .88× .09 | 26 | 72176756 | O-Ring, 3.88×4.25× .19 | 6 | ||

| 13 | 72141569 | Kit, Proximity Switch | 2 | ||||

| 72134224 | Proximity Switch | ||||||

| 95119012 | Socket Head Screw, 1/4-20×1 |

The winwin waterjet UHP 90K pump is another type of high-pressure intensifier pump used in waterjet cutting machines. It is manufactured by winwin Waterjet Systems, a company that specializes in the design and manufacturing of waterjet cutting pumps and components.

A waterjet UHP (ultra-high pressure) 90k intensifier pump is a device that generates high-pressure water for use in waterjet cutting systems. The “90k” specification refers to the pump’s ability to generate pressures of up to 90,000 pounds per square inch (psi).

The pump works by taking in water from a source and pressurizing it using a series of pistons and cylinders. The pressurized water is then directed through a nozzle, where it can be used to cut through a variety of materials, including metal, el plastico, and wood.

UHP waterjet cutting systems are often used in industrial applications, such as cutting metal parts for manufacturing or precision cutting of materials for aerospace and defense applications. They offer a number of advantages over traditional cutting methods, including the ability to cut complex shapes with high precision and minimal waste.

The winwin 90K pump is capable of producing water pressure up to 90,000 PSI, and is known for its reliability, efficiency, and high performance. It uses an intensifier to amplify the input pressure and create a high-pressure water stream that can be used for cutting a wide range of materials.

The winwin 90K pump is available in several different models, each with its own unique features and specifications. These pumps are typically used in industrial settings, such as manufacturing facilities, where precision cutting of hard materials is required.

The high-pressure water stream produced by the KMT 90K pump can be used to cut through a wide variety of materials, including:

Metals: The winwin 90K pump can cut through different types of metals, including steel, aluminio, copper, and titanium. The Waterjet 90k Intensifier high-pressure water stream can create precise cuts in these materials without generating heat-affected zones or distorting the material.

Stone: The winwin 90K pump is also capable of cutting through stone materials such as granite, mármol, and limestone. The high-pressure water stream can create intricate designs and shapes in these materials with a high degree of accuracy.

Glass: The winwin 90K pump can also be used to cut through glass materials, including tempered glass, laminated glass, and stained glass. The high-pressure water stream can create clean cuts in glass without causing any cracks or chips.

Composites: The winwin 90K pump can cut through composite materials, such as Waterjet 90k Intensifier carbon fiber, fiberglass, and Kevlar. These materials are often used in aerospace and automotive industries and require precise cutting.

Plastics: The winwin 90K pump can cut through different types of plastics, including acrylics, polycarbonates, and polyethylene. The high-pressure water stream can create precise cuts in these materials without generating heat or leaving any burrs.

En general, the winwin 90K pump is a versatile tool that can cut through a widerange of materials with precision and efficiency, making it a popular choice in various industries.

Here are some features of a waterjet 90k intensifier pump:

1.High-pressure output: The pump is capable of generating pressures of up to 90,000 psi, which is necessary for cutting through hard materials like metal and stone.

2.Precision cutting: Waterjet cutting systems are able to cut with high precision, often with tolerances of +/- 0.003 inches.

3.Versatility: Waterjet cutting systems can be used to cut a variety of materials, including metal, el plastico, madera, stone, and composites.

4.Minimal material waste: Waterjet cutting creates narrow kerfs, which means less material is wasted compared to other cutting methods.

5.No heat-affected zone: Waterjet cutting does not generate heat, which means there is no heat-affected zone (HAZ) in the material being cut. This is particularly important in materials that are sensitive to heat, such as certain types of plastics.

6.Environmentally friendly: Waterjet cutting systems do not create hazardous waste or emit harmful gases, making them environmentally friendly.

7.Low maintenance: Waterjet pumps are designed to be low-maintenance and can operate for long periods of time without requiring significant maintenance.

- Easy to use: Waterjet cutting systems are relatively easy to operate, and the software used to control the cutting process is user-friendly and intuitive.

9.3D cutting capability: Waterjet cutting systems can cut in 3D, allowing for the creation of complex shapes and contours.

10.Cold cutting: Waterjet cutting is a cold cutting process, which means it does not generate heat or cause thermal distortion in the material being cut.

11.No tool wear: Waterjet cutting does not cause tool wear, unlike traditional cutting methods that use saws, drills, or milling machines.

12.High-speed cutting: Despite the high pressure required, waterjet cutting is a relatively fast cutting method, especially compared to manual cutting processes.

13.No need for secondary finishing: The edge quality of waterjet-cut parts is often high enough that there is no need for secondary finishing operations, such as sanding or deburring.

14.Safe and quiet operation: Waterjet cutting is a safe and quiet cutting process, with minimal noise and no hazardous fumes or dust.

15.Reduced risk of material contamination: Waterjet cutting does not use any cutting fluids or lubricants, which reduces the risk of material contamination.

En general, a waterjet 90k intensifier pump is a powerful and flexible cutting tool that offers a range of benefits over traditional cutting methods. It is particularly useful for cutting hard, thick, or complex materials, and is often used in applications such as aerospace, automotor, and metal fabrication.

The winwin waterjet 90k intensifier pump is a highly versatile and Waterjet 90k Intensifier efficient cutting tool that offers many benefits over traditional cuttingmethods. Its ability to cut through hard materials with high precision and minimal waste makes it a popular choice for a variety of industries, including aerospace, automotor, and manufacturing. Additionally, waterjet cutting is a safe and environmentally friendly cutting method that operates quietly and does not produce hazardous waste or emissions.

16.Low maintenance requirements: Waterjet cutting systems are designed to be low-maintenance and can operate for long periods of time without requiring significant maintenance. This can reduce downtime and increase productivity.

17.High cutting speeds: Despite the high pressure required, waterjet cutting is a relatively fast cutting method, especially Waterjet 90k Intensifier compared to manual cutting processes. This can improve productivity and reduce lead times.

18.Precise and accurate cutting: Waterjet cutting systems can cut with high precision and accuracy, often with tolerances of +/- 0.003 inches. This can improve part quality and reduce the need for secondary operations.

19.Non-contact cutting: Waterjet cutting is a non-contact cutting method, which means there is no physical contact between the cutting tool and the material being cut. This reduces the risk of damage to the material and extends the life of the cutting tool.

20.Ability to cut a wide range of materials: Waterjet cutting systems can cut a wide range of materials, including metals, plastics, composites, ceramics, vaso, and stone. This makes it a versatile cutting method for a variety of industries.

21.Easy to automate: Waterjet cutting systems can be easily automated using computer numeric control (CNC) software, which allows for high-precision cutting and improved productivity.

22.Improved safety: Waterjet cutting Waterjet 90k Intensifier is a safe cutting method, with minimal noise and no hazardous fumes or dust.Additionally, the cutting process is enclosed, which reduces the risk of operator injury from flying debris or accidental contact with the cutting tool.

23.Reduced tooling costs: Waterjet cutting does not require expensive tooling, dies, or molds, which can reduce tooling costs and lead times.

24.Flexibility in design: Waterjet cutting allows for the production of complex shapes and designs with ease, which can lead to more innovative and creative products.

25.Minimal part distortion: Waterjet 90k Intensifier cutting does not cause part distortion or warpage, which can improve part quality and reduce the need for secondary operations.

Reseñas

Aún no hay reseñas.