Beschreibung

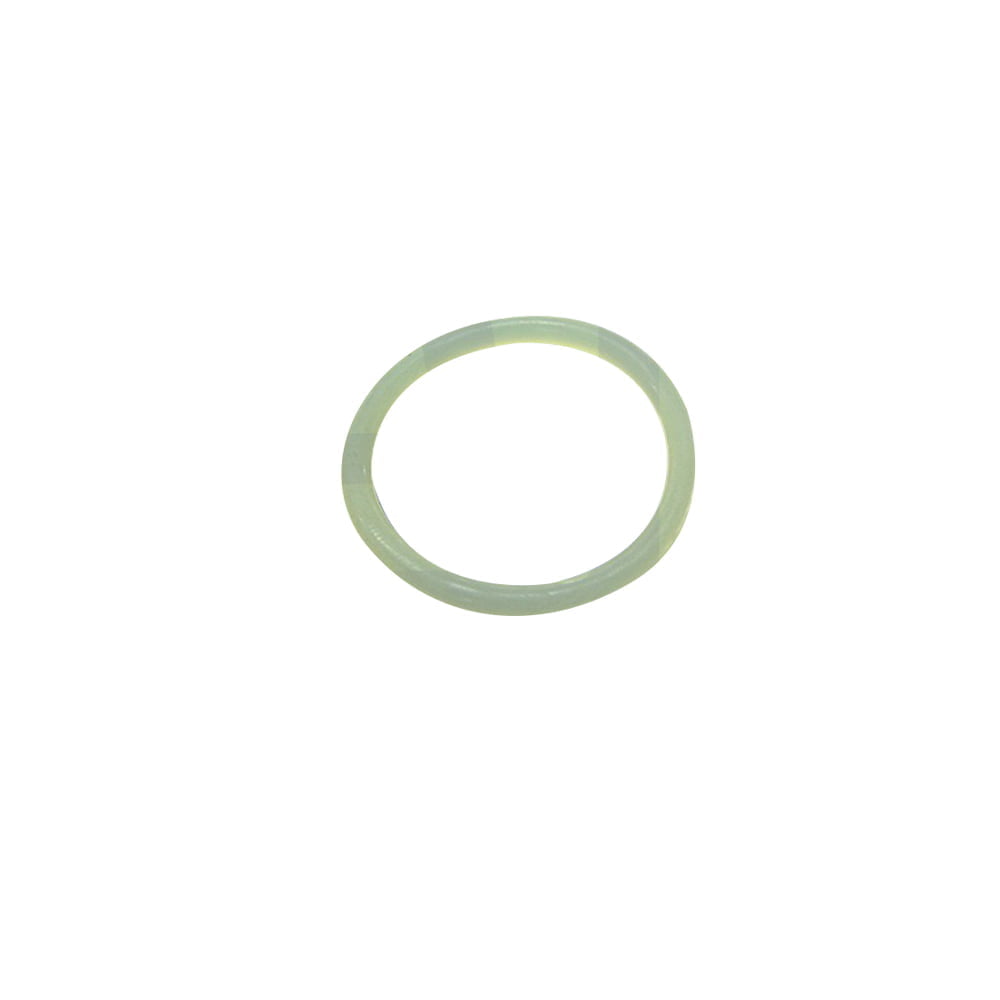

Waterjet Piston O-Ring, 1.25 X 1.50 X .13 05087713

Waterjet Piston O-Ring, 1.25 X 1.50 X .13 05087713 Wird für die SL-VI 50HP-Pumpe verwendet

Hydraulic Piston Assembly

| Artikel | Part Number | Beschreibung |

| 1 | 05132261 | Ram Piston, 4.03 |

| 2 | 05074380 | Clevis Pin |

| 3 | 05049887 | Setscrew |

| 4 | 10148757 | Check Valve Assembly |

| 5 | 05088364 | Haltering |

| 6 | 05049994 | Backup-Ring, 1.25 X 1.50 |

| 7 | 05087713 | O-Ring, 1.25 X 1.50 X .13 |

| 8 | 05117965 | Dichtungsmontage |

| 9 | 05117940 | Bearing |

What are some factors causes of waterjet piston O-ring failure?

There are several common causes of waterjet piston O-ring failure in hydraulic and pneumatic systems:

Wear and Tear: Waterjet piston O-ring is subjected to regular wear and tear from the constant movement of the piston rod. Over time, this can cause the O-ring to degrade, crack, or break, which can lead to leaks.

Improper Installation: If the O-ring is not installed correctly, it can become twisted, pinched, or damaged during assembly.

Contamination: If the hydraulic or pneumatic system becomes contaminated with dirt, debris, or other foreign particles, it can cause the O-ring to wear or fail more quickly than normal.

Chemical Attack: Some fluids used in hydraulic and pneumatic systems, such as acids or solvents, can attack the O-ring material and cause it to degrade or break down.

Incompatible Materials: If the O-ring material is not compatible with the fluid being used in the system, it can cause the O-ring to swell, harden, or break down, leading to premature failure.

Overheating or Over-Pressurization: If the system is subjected to high temperatures or pressures beyond its design limits, it can cause the O-ring to fail.

To prevent waterjet piston O-ring failure, it is important to choose the right O-ring material for the system’s operating conditions, install the O-ring correctly, and maintain the system properly.

Bewertungen

Es gibt noch keine Bewertungen.