Description

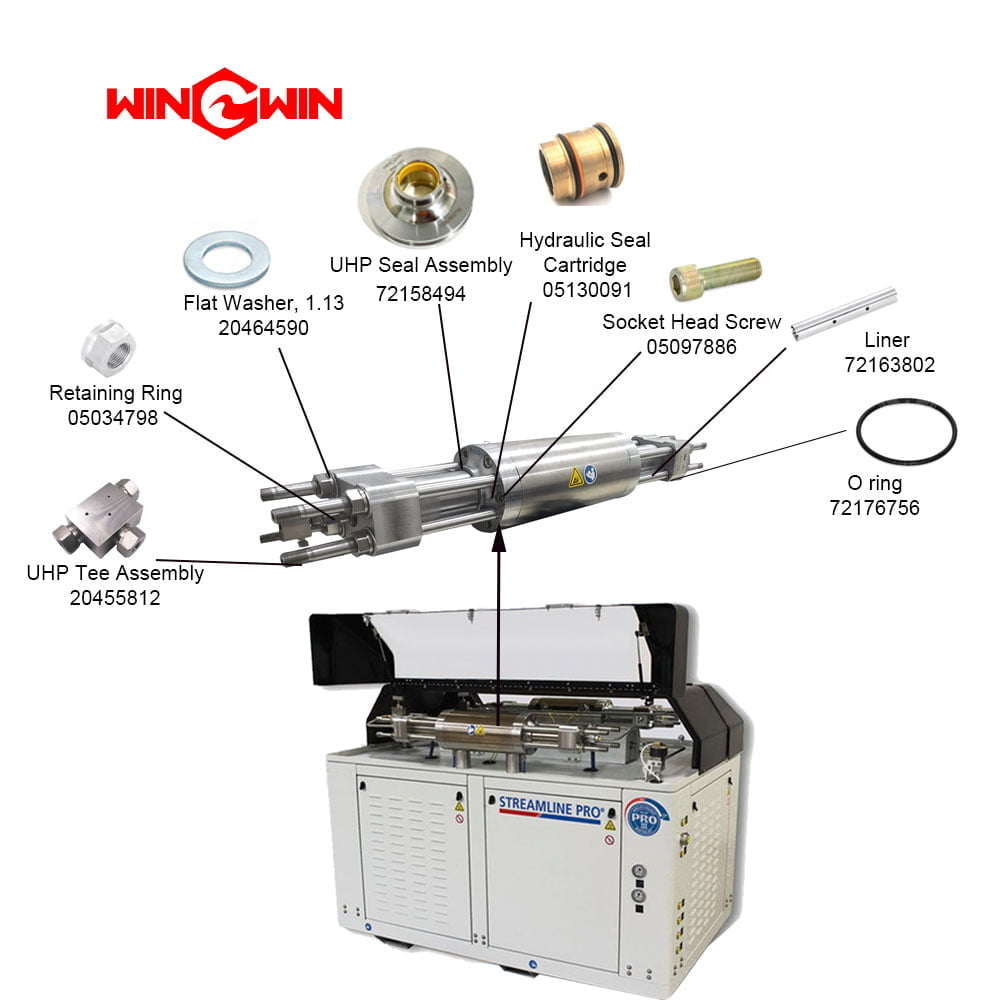

waterjet parts 05130091 Hydraulic Seal Cartridge

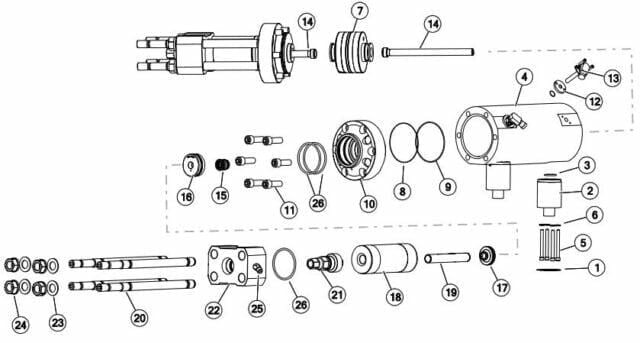

Figure 12-3: Hydraulic Seal Cartridge

05130109 Seal Bushing 1 2 05015060 Packing Ring 2

3 10193522 O-Ring, 1.19 x 1.38 x .09 1

4 05050760 Backup Ring 1

5 05129481 O-Ring, 1.0 x 1.13 x .06 1

6 05013024 O-Ring, 1.25 x 1.38 x .06 1

7 05129515 Backup Ring 1

8 05027255 Packing Seal 1

a hydraulic seal cartridge used in a waterjet cutting machine. Hydraulic seal cartridges are used in the hydraulic system of the machine to prevent leaks and ensure proper functioning of the system.

The hydraulic system in a waterjet machine is responsible for powering various components such as the cutting head, intensifier pump, and other systems. The seal cartridge you mentioned is likely used to seal hydraulic fluid at a specific point in the system, such as at a piston or valve.

If the hydraulic seal cartridge in your waterjet machine is damaged or worn out, it can cause leaks and reduce the efficiency of the hydraulic system. waterjet parts 05130091 Hydraulic Seal Cartridge Replacing the seal cartridge is an important part of regular maintenance for a waterjet cutting machine.

Waterjet cutting machines require regular maintenance to ensure optimal performance and longevity. Here are some common maintenance procedures for waterjet cutting machines:

- Check and replace worn or damaged parts: Regularly inspect your waterjet cutting machine for any signs of wear or damage, such as worn seals, waterjet parts 05130091 Hydraulic Seal Cartridge damaged hoses, or worn-out nozzles. Replace any worn or damaged parts to prevent leaks and ensure proper functioning of the machine.

- Clean and maintain the high-pressure system: The high-pressure system in a waterjet cutting machine requires regular cleaning and maintenance, such as flushing the system with clean water and inspecting the high-pressure lines for any signs of wear or damage. It’s also important to replace the high-pressure seals and check the intensifier pump regularly.

- Clean and maintain the abrasive delivery system: The abrasive delivery system in a waterjet cutting machine requires regular cleaning and maintenance to waterjet parts 05130091 Hydraulic Seal Cartridge prevent clogs and ensure proper functioning of the machine. This includes cleaning the abrasive hopper, checking the abrasive flow rate, and inspecting the abrasive delivery lines for any signs of wear or damage.

- Lubricate moving parts: Regularly lubricate the moving parts of your waterjet cutting machine, such as the gantry system and the cutting head, to prevent wear and ensure smooth movement.

- Inspect and maintain the control system: The control system in a waterjet cutting machine requires regular inspection waterjet parts 05130091 Hydraulic Seal Cartridge and maintenance to ensure proper functioning of the machine. This includes checking the software and hardware components, aswell as the electrical connections and wiring.

- Regularly replace filters: Waterjet cutting machines use filters to remove impurities from the water and abrasive. It’s important to regularly replace these filters to ensure proper functioning of the machine and prevent contamination of the water and abrasive.

- Keep the machine clean: Regularly clean the machine, including the cutting bed, to prevent buildup of debris and to maintain a clean work environment.

- Train operators: Proper training of machine operators is essential to waterjet parts 05130091 Hydraulic Seal Cartridge ensure safe and efficient operation of the machine. Make sure waterjet parts 05130091 Hydraulic Seal Cartridge your operators are properly trained on the operation and maintenance of the machine.

المراجعات

لا توجد توصيات بعد.