Description

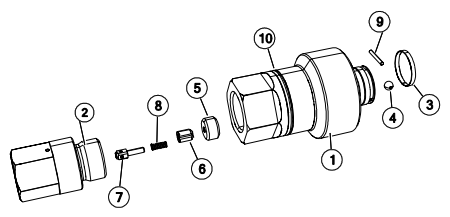

water jet 90k spare part 05116751 Poppet Pin

The water jet 90k spare part 05116751 Poppet Pin is a component of the high-pressure waterjet system that helps to hold the discharge poppet in place within the high-pressure cylinder of the pump. The water jet 90k spare part 05116751 Poppet Pin is responsible for preventing the poppet from moving or coming loose during operation.

The water jet 90k spare part 05116751 Poppet Pin is a specific replacement part designed for water jet 90k pumps. It is made from high-quality materials and is designed to meet the exact specifications of the original equipment manufacturer. This ensures that the poppet pin will provide a reliable and durable hold for the system, helping to prevent unwanted movement or disassembly during operation.

Replacing the poppet pin is an important maintenance task for any high-pressure waterjet system. Over time, the poppet pin can become worn or damaged, which can lead to the poppet becoming loose or disassembling during operation. This can cause a variety of issues, including leaks, loss of pressure, and reduced cutting performance. By replacing the poppet pin with a high-quality replacement part like the 05116751, you can ensure that your water jet 90k system will continue to operate with maximum efficiency and reliability.

The frequency of replacing the water jet 90k spare part 05116751 Poppet Pin will depend on several factors, including how frequently the pump is used, the type of materials being cut, and the operating conditions of the system. As a general guideline, it is recommended to inspect the poppet pin regularly and replace it asneeded to prevent unwanted movement or disassembly during operation. If you notice any issues with the poppet becoming loose or disassembling during operation, this could be an indication that the poppet pin needs to be replaced.

Regular maintenance and inspection of your waterjet system can help to prevent premature wear and damage to the poppet pin and other components. This includes routine cleaning, lubrication, and inspection of the high-pressure cylinder and other parts. Be sure to follow the manufacturer’s recommended maintenance schedule and guidelines to ensure that your system operates with maximum efficiency and reliability.

Reviews

There are no reviews yet.